Arm testing is becoming increasingly important in the modern age, as businesses seek to protect their digital assets and keep their systems resilient to attacks. Recently, Google announced a $25M investment to accelerate arm testing, bringing it to the forefront.

In this article, we’ll explore the importance of arm testing, and why businesses must invest in it for greater cybersecurity.

The current state of arm testing

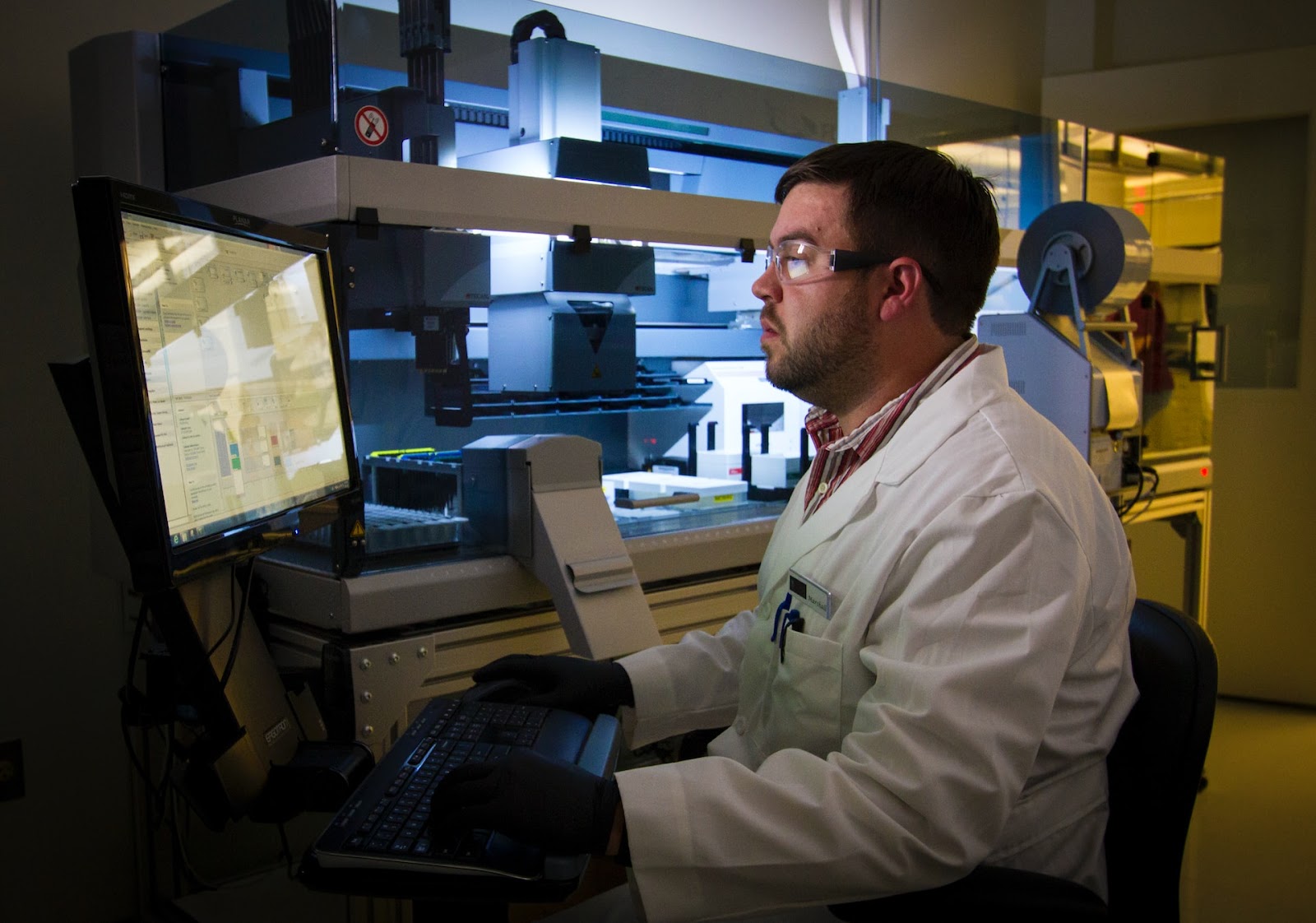

Manual arm testing is the traditional method used to assess upper limb strength and endurance. This process involves manually manipulating the arm, hand, wrist and fingers into various positions with instructions from a clinician. Although this method has been used for decades and is still widely used, several drawbacks are associated. First, it is time-consuming as each test must be repeated several times to obtain reliable results. Second, due to the physical contact required when conducting manual tests, potential contamination can occur or the patient’s comfort level may be affected.

New technologies such as automated arm testing have emerged to overcome these issues in recent years.

Automated arm testing uses computerized programs that assess strength and endurance by attempting to move joints to detect residual muscle force generated by the body’s muscles and muscles in combination with external forces applied through braces or supports. This type of testing relies upon sophisticated algorithms which can accurately measure forces without putting strain on patients or causing them discomfort. Automated tests are also more efficient as they provide fast and precise results which can be stored for future reference or comparison purposes. Consequently, automated arm testing is becoming increasingly popular within medical settings due to its convenience and accuracy compared to traditional assessment methods.

The importance of arm testing

Arm testing is important for safety testing for mechanical components such as robotics or aerospace. It involves using a force testing apparatus to measure the force that can be safely applied to an arm or other component without causing damage. The ability to test arm components safely and accurately ensures safe and reliable operation, which is critical in industries where safety is paramount.

Arm testing evaluates the strength, stiffness, fatigue resistance, wear resistance, corrosion resistance and tear strength of different components. It can also be used to evaluate parameters associated with movement such as range of motion, skill and agility. Arm testing machines are designed to exert pressure on the component under test while measuring signals that indicate the level of stress on the component at any time. The results will allow engineers and designers to develop better products with improved performance characteristics.

The results obtained from arm testing can help optimize a product design, increase safety margins and save money by ruling out potentially disastrous design flaws before they go into production. Furthermore, they provide valuable insight into how different materials perform under various conditions so that future products can be designed more efficiently with fewer components needed for successful operation.

The Benefits of Arm Testing

Arm testing is an important process for ensuring the reliability of products during the development phase. In 2021, the government announced $25M to accelerate arm testing, indicating its importance as a valuable tool.

There are several benefits associated with arm testing and this article aims to provide an insight into these advantages.

Improved safety

Arm testing, also known as hand-arm vibration monitoring, is a method used to measure and record the amount of exposure an individual has to hand-arm vibration. This system allows businesses and organizations to ensure compliance with Occupational Safety and Health Administration (OSHA) regulations. It is an important safety practice that can improve workplace conditions for all employees.

Arm testing aids in protecting employees from the potential long-term damage that might result from long-term exposures to vibration. By using arm testing, employers can assess how much exposure their workers receive over a certain period from various equipment and tools they use. This assessment should be completed regularly throughout the year to detect any potential hazards associated with existing work tasks or machines in the environment.

Improving safety with arm testing involves numerous steps. First, businesses must create policies requiring appropriate controls when assessing real or possible risks related to vibration exposure. This includes ensuring that all employees are educated about the harmful effects of vibrations and receiving appropriate training for health screenings before beginning work tasks involving high levels of vibration. After determining which tools pose the highest risk, employers should develop plans to reduce those risks through measurement at intervals throughout each employee’s shift duration or total work time as well as provide personal protective equipment when necessary. Finally, businesses should have processes in place for proper monitoring and maintenance of machines and tools used by their employees so that any hazardous machines can be identified quickly before they cause harm or injury among workers operating them.

Increased efficiency

Arm testing can drastically improve the efficiency of a facility’s operations. It can also be used to monitor and compare the performance of individual personnel over time. By tracking progress and allowing for easy adjustments and updates, arm testing can help employees’ performance stay consistent and well-measured to ensure that production lines run efficiently.

Additionally, arm testing can optimize task timing, allowing employers to make quick decisions on the effectiveness of processes or shifts. Employees can also immediately provide feedback on any issues, allowing for corrective action that would otherwise be difficult to determine in standard operational procedures. Finally, processes records are kept easily through arm testing, allowing for data accumulation and analysis to further optimize facility flow.

In this way, arm testing gives employers an increased insight into company operations. It allows them to act quickly on any changes that might become necessary to maintain success or significant growth potentials. It is a powerful tool that should not be overlooked as an important element in managing any sized organization or operation.

Reduced costs

Arm testing can help reduce costs associated with tooling, manpower, and other materials. By using arm testing, manufacturers can develop highly accurate tests to ensure the performance of products without costly production runs or labor intensive visual inspections. In addition, this process can be more reliable than manual inspections, avoiding hidden defects and improving quality control across multiple manufacturing sites.

Arm testing also eliminates the need for multiple test jigs and fixtures, allowing a single device to collect data from several parts or components simultaneously. Additionally, time-consuming trial and error processes are eliminated with arm testing as these devices have built-in sensors that allow manufacturers to quickly tweak machine parameters to achieve optimal performance with much less effort. This reduces manufacturing errors and waste while improving the predictability of product results.

Challenges of Arm Testing

Arm testing is an important process for companies regarding product development and device certification. From $25 million invested in 2020 to accelerate arm testing to introducing new regulations and standards, arm testing has become increasingly important.

However, it can also be complicated and time-consuming. In this article, we will discuss some of the challenges of arm testing and how to overcome them.

Lack of standardization

The lack of standardization has historically been one of the biggest challenges of doing arm testing. No single test approach can be applied to all objects, as an item’s physical and functional characteristics can vary greatly. In addition, environmental conditions such as temperature, humidity, and other external factors also significantly affect the results.

Furthermore, different test methods require different skill levels and expertise to be performed accurately. This can make it difficult for inexperienced or untrained testers to interpret results properly or act upon them. As a result, establishing clear test protocols and training records are essential when doing arm testing.

It is also important to note that arm testing must take into account considerations such as operator familiarity, equipment availability and its suitability for purpose when performing tests. Therefore, establishing specific criteria for selecting suitable test methods based on their effectiveness in delivering desired results is highly recommended when conducting arm testing for commonly found objects in production environments.

Technical complexity

Arm testing is a highly complex process requiring close attention to detail to achieve quality results. Due to its technical complexity, arm testing can be very labor-intensive and it can take several hours for a skilled technician to properly determine the arm’s parameters. In addition, the technician must comprehensively understand the physics and mechanics of motion control before performing an accurate and reliable arm test.

Furthermore, application-specific test methods must be designed according to your requirements to accurately diagnose issues with your robotic system. Depending on these requirements, a comprehensive evaluation process must be applied to the robotic arm before operations. This includes performing tests such as alignment accuracy, repeatability and positioning accuracy tests to determine how precisely the robotic arm can move within its design limits. These tests can be especially complex if multiple linked arms or your production system involves external components or sensors.

Additionally, environmental factors such as temperature changes or high humidity levels can also negatively affect the results of an arm test if not considered during testing procedure development. Finally, some processes may require custom software algorithms for analyzing movement quality for developers to adjust their robot arm’s overall setup and operation.

Limited resources

When considering arm testing for products such as medical devices, it is important to consider financial resources and time constraints. In most cases, arm testing is conducted on a limited budget and with a limited timeline. This can be especially challenging when dealing with multiple models of medical devices or devices from different manufacturers.

In addition, due to the complexity of the design and development process for medical devices, it can be difficult to know where the limitations in resources should lie and how much should be invested in arm testing.

Furthermore, while performing arm tests on products before they are released onto the market allows manufacturers to identify any potential issues before they become a problem for consumers, some flaws may only appear in certain environmental conditions or after extended use that may not occur until after the product has already gone through its initial phase of testing. Manufacturers must therefore consider how they will address potential problems after launch if arm tests cannot detect all present issues beforehand.

$25M to accelerate arm testing, research, and development

To advance the development of automated driving systems, the National Highway Traffic Safety Administration (NHTSA) has announced an investment of $25 million to accelerate the testing and validation of automotive arm technologies.

This funding is expected to increase the speed of developing arm-driven vehicles. This article will explore what arm technologies are and how this investment can help spur the development of these autonomous systems.

Overview of the initiative

To advance the understanding of the movement of mobile robot arms, the National Science Foundation (NSF) is providing US$25M to fund a research initiative in 31 developments across 12 states. This will create new opportunities for robotic engineers and researchers to test and study the various complexities of arm end-effectors.

This project’s scope is founded on enabling robots to aid in hazardous production processes and build assets, such as robots assisting in quality control by automatically testing cables. In addition, this project will include some direct applications in medical environments, such as assembling medical instruments with pinpoint precision or improving surgical accuracy through corrective feedback systems.

This project provides a comprehensive array of challenges for robotic researchers who wish to explore mobile robotics control using advanced software solutions that are mostly theoretical. The aim here is not only to discover technology gaps but also check whether human intervention can be reduced while maintaining safety and accuracy at the same time.

The NSF believes this substantial investment could fundamentally alter how robot arms are tested today — potentially revolutionizing traditional robotics testing methods while reshaping what is possible from end-effectors. Moreover, by creating a sustainable development infrastructure through support from diverse researchers—from engineering backgrounds ranging from neuroscience to applied robotic engineering—the NSF hopes these innovations will lead to substantial opportunities for key industry players over the next decade or two.

Goals of the initiative

The $25 million initiative is intended to accelerate the development and use of arm testing, a powerful tool to help researchers better predict medicinal efficacy and toxicity outcomes in preclinical studies.

By enhancing the scientific rigor of preclinical research, arm testing can reduce drug development timelines, helping make medicines available more quickly for patients in need. In addition, this initiative will provide direct support for those engaged in discovery activities related to arm testing.

Through this initiative, we hope to:

- Develop a better understanding of the mechanisms driving various diseases to maximize efficacy outcomes;

- Accelerate advances in understanding how drugs interact with varying genetic profiles;

- Increase understanding regarding differences in drug responses among different patient populations;

- Enhance predictive power by combining nonclinical and clinical studies data on the same molecule.

Potential impact of the initiative

The Department of Defense’s (DOD) $25 million initiative to accelerate arm testing could have a wide ranging and highly positive impact on the security and safety of service members. The new program will emphasize arm testing, creating more robust and reliable standards, procedures, assessments, technology monitoring and tools. The initiative also aims to improve communication between different arms stakeholders and enhance collaboration across military branches.

The initiative is expected to help create more realistic training environments that better simulate battlefield conditions while increasing the testing required by weapons manufacturers. This could improve quality control, ensure that weapons perform as specified when they reach service members in the field and reduce the chances of a malfunction or failure in a high-stress environment. In addition, this increased level of thoroughness in arm testing should improve soldiers’ accuracy and greater confidence in their equipment’s abilities when engaged in combat operations.

Overall, this new program could lead to faster innovation as technologies are introduced at an accelerated rate due to improved end-to-end testing standards. As well as providing greater security for soldiers using these advanced arms systems, this likely increase in innovation should benefit all branches of defense with improved capabilities against any potential threats that could arise against US interests domestically and abroad.

Conclusion

In conclusion, arm testing is essential to any software development process. It can help ensure that the software meets performance and reliability requirements while providing a measure of security.

A $25M investment from the U.S. The Department of Defense to accelerate arm testing indicates the importance of this testing and the need to ensure arm software is secure and reliable.